|

Innovative Engineering and Business Solutions |

![]()

|

|

|

|

We offer a complete product development services including Design, Construction. Available staffing offers a combined experience of over 200 years. Key Benefits

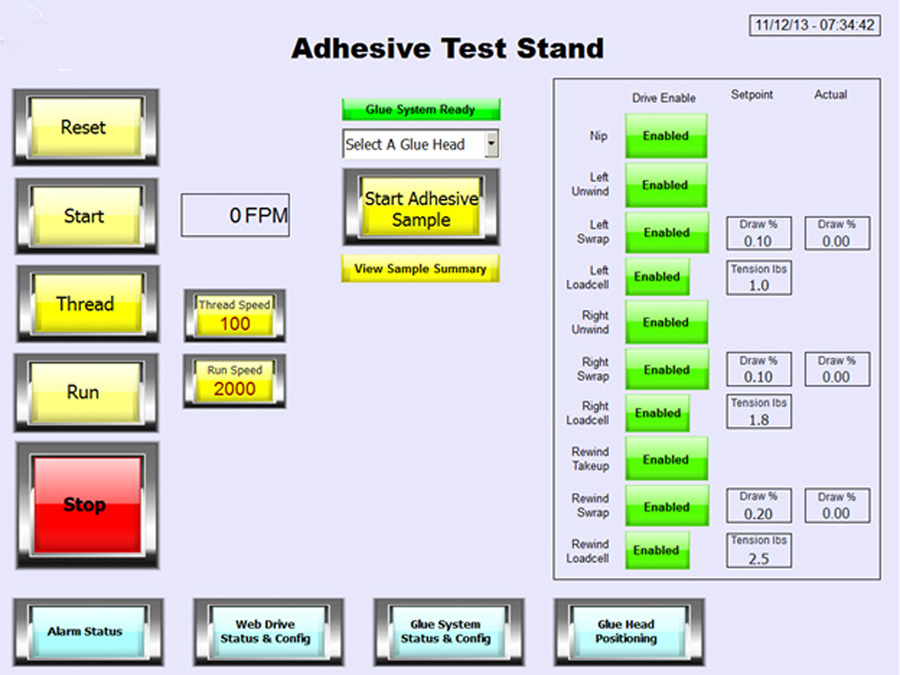

Example of a recent project: A client, who manufactures adhesives, needed lab equipment that would allow the preparation of experimental adhesive lamina samples, using their customer's substrates. The machine was required to support a variety of commercially available application technologies. The machine we designed and built allowed for the assembly of a wide variety of lamina at speeds to 2000 ft/min with independent tension controls of both incoming substrates and combined web, with acceleration of up to 400 ft/min/sec. The mechanical design included precision ground mechanical tubes by Hamilton Precision , Middletown, Ohio and precision machined Alcoa MIC-6 tooling plate prepared by Narrow Way Technologies Franklin, Ohio. The installed machine was aligned to .004" end to end and top to bottom by The Fenton Rigging Company, Cincinnati, Ohio. This machine was constructed and commissioned in 8 months.The Overall Design: Length

28 ft.

Fully Guarded Operator Side of Adhesive Development Machine

Drive Side of Machine

HMI Panel

UL

Certified Machine Control Panel

For additional information please complete the following form and "submit" so we can contact you.

|